20 High Street, Plainville, MA 02762

info@teambes.com

Highly automated structural steel processing that is American Made and produced with local forces with great precision. This process takes talent, focus and skill. Though structural steel raw material is sold as commodity, the process and who is behind making it all into a building takes incredible skill and talent.

The Process

Step 1

Step 2

Step 3

Step 4

Step 5

Step 6

Step 7

Step 8

Step 9

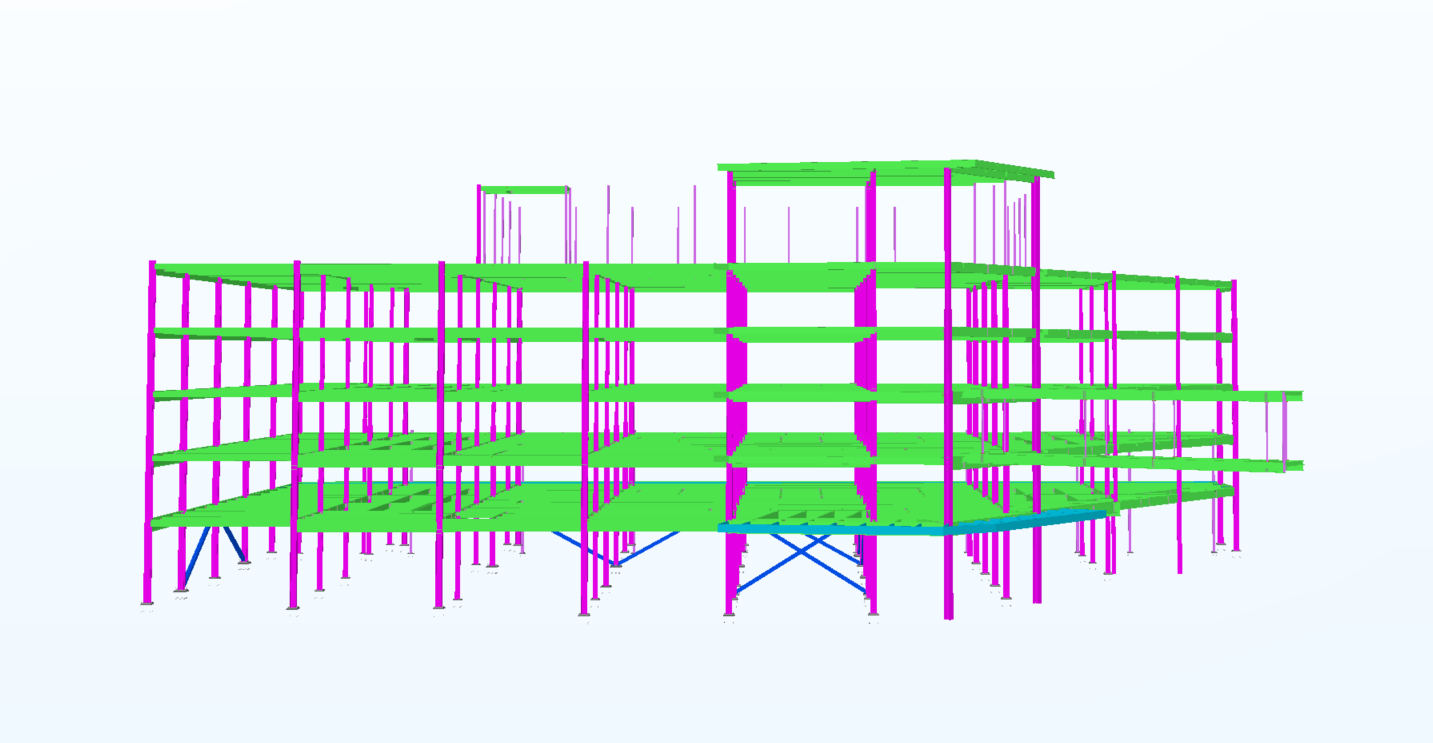

3D Modeling

We utilize 3D models in many ways. 3D models allow us to better visualize a project, as opposed to just 2D plans. This helps us understand the wishes of the client and owner. Modeling a job lets us estimate quicker by ensuring all pieces are accounted for, and allows us to continue to provide competitive pricing for our clients.